-

Sign Up! To view all forums and unlock additional cool features

Welcome to the #1 Explorer ST Forum and Explorer ST community dedicated to Explorer ST owners and enthusiasts. Register for an account, it's free and it's easy, so don't hesitate to join the Explorer ST Forum today!

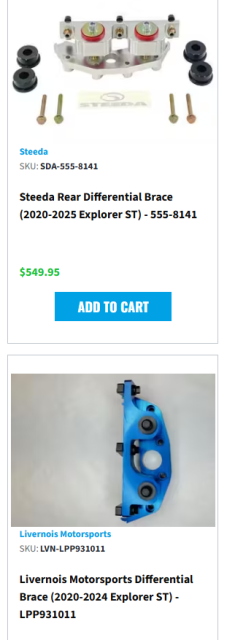

Rear differential brace Steeda, Livernois, ID speed

- Thread starter Ecobeast3

- Start date

- Messages

- 2,906

- Reactions

- 1,306

- Points

- 252

- Location

- Nevada

- Vehicle

- '20 Raptor, '22 Explorer ST, '14 GT500, '03 F150

The Livernois one at least looks good, Steeda one sucks. What exactly makes the Livernois unit inferior to the ID-Speed?

Thread Starter

#6

I’ve said a thousand times these double braces aren’t needed. There’s no reason to lock the rear diff down solid on a daily driver. The ID Speed brace was actually engineered to work like a 4 bolt car.

- Messages

- 2,906

- Reactions

- 1,306

- Points

- 252

- Location

- Nevada

- Vehicle

- '20 Raptor, '22 Explorer ST, '14 GT500, '03 F150

What about on a 2-bolt rear subframe car?

-

1

- Show All

- Messages

- 2,906

- Reactions

- 1,306

- Points

- 252

- Location

- Nevada

- Vehicle

- '20 Raptor, '22 Explorer ST, '14 GT500, '03 F150

I like the JXB inserts for 4 bolt cars…they do work and do exactly what they claim. Unfortunately I have some NVH increase and removed them but many haven’t had that experience.

Do you think they’ll do the job alone without a diff brace with stopping the bushing from failing? I remember Tyler’s old car (which was a 2-bolt) bushing failed after quite a few launches he does.

I have the Steeda. I actually don't have it connected because of NVH issues. Although it may not be common to the Steeda as I am sure there would be more posts about it. I get a very noticeable humming noise that seems to be transmitting from either the rear diff pinion or carrier bearings. Not noticable without the brace though and thus not enough for Ford techs to replicate it.

We’ve had a lot of very satisfied customers with this upgrade—while I can’t share exact sales numbers, I can say the response has been outstanding since we introduced it. I’m happy to help you with a Steeda unit and can offer preferred forum pricing. Feel free to reach out to me directly at [email protected].

-

3

- Show All

I have the Steeda. I actually don't have it connected because of NVH issues. Although it may not be common to the Steeda as I am sure there would be more posts about it. I get a very noticeable humming noise that seems to be transmitting from either the rear diff pinion or carrier bearings. Not noticable without the brace though and thus not enough for Ford techs to replicate it.

-

1

- Show All

I'm on my 3rd rear diff and 2nd driveshaft and the dealer can't find this noise. Mine's at 45 mph and 58-62 mph, accel and decel, but louder at decel. Throwing a carrier bearing at it, don't know what else to try. AWR brace on mine is almost like a stethoscope to an underlying issue. I did some research on the FB group and this is an issue with all braces for a very small number of people. My '22 was dead quiet, in the '23 I can't cover the noise with the radio.

Mine all started last fall. I did have my brace on for about 3-4 months and had not issues. Right about 95,000 miles. I do second it when it starts making the noise nothing covers it up.

Appreciate everyone sharing their experiences here — doing research for my next build and found this thread incredibly helpful.

Had a ’22 Platinum that I sold for a different platform, now coming back to do a full build on a ’25 Platinum (converting it to ST specs like last time). Spent considerable time researching the diff brace landscape and wanted to share my findings — both to help others and get feedback from those further along.

Brace Comparison: Key Options for the Platform

ID Speed ($499)

• Most consistent praise across Explorer builds

• Engineered like a 4-bolt system

• Uses EPDM bushings for superior NVH control vs. poly

• Ideal for daily-driven or mixed-use builds

• No major complaints found during research

AWR Racing ($280)

• Excellent value option with solid design

• However, some concerning red flags:

• Marketing claims about police fleet use unverifiable

• “Lifetime warranty” contradicted by fine print (“racing use only”)

• Works well for many, but integrity concerns may be dealbreakers for premium builds

Steeda ($550)

• Multiple reports of excessive NVH

• Design appears too rigid for daily-driver comfort

• Documented mounting bolt failures under load

Livernois (SEMA 2024 release)

• Similar to Steeda design but not identical

• Uses premium ARP hardware

• Too new for real-world data

• Like Steeda, appears better suited for track use due to stiffer design

Bottom Line

• Go ID Speed if budget allows – best engineering, clean install, solid support, minimal NVH

• AWR works but proceed cautiously – great price, questionable marketing

• Avoid Steeda unless prioritizing track times over comfort

• Livernois is unproven – worth monitoring but not recommended (yet) for daily builds

Troubleshooting NVH or Whine After Brace Install

Something that kept appearing across platforms — Mustang, Camaro, Trackhawk, Explorer:

Braces rarely cause noise. They reveal it.

Installing a brace replaces soft factory bushings with solid mounts, transmitting more vibration and sound into the chassis. Early wear in your pinion bearing, gear mesh, or carrier preload — previously masked — suddenly becomes audible.

If You Hear New Noise After Install

1. Don’t assume the brace is to blame

• Remove the brace temporarily. If noise disappears, the problem was likely already developing inside the diff.

2. Log noise patterns

• Speed (45–50 mph, 58–62 mph are common problem zones)

• Throttle input (accel vs. decel)

• Temperature, road surface, etc.

→ Helps differentiate gear whine from bearing drone or bushing resonance.

3. Send diff fluid for analysis

• Use a lab like Blackstone

• High iron = bearing wear

• Brass/bronze = gear or thrust washer wear

→ Confirms preexisting issues.

4. Check for Ford TSBs

• Some Explorer models have known diff/pinion issues

• The brace might simply be surfacing a documented problem

5. Verify brace torque and alignment

• Over-tightened or misaligned installations can cause vibration

• Confirm clean seating, correct torque spec, and no diff preload

6. Use chassis mic or mechanic’s stethoscope (if available)

• Helps isolate whether sound originates from diff, half shafts, or elsewhere

• This approach saved several users from misdiagnosing axle issues as diff problems

Final Thought

• If a brace makes something louder — it may be doing you a favor.

• Better to hear early-stage wear now than experience a $3000+ failure later.

• Whether you’re building from scratch or doing a conversion like me — understanding what the brace isn’t doing is just as important as knowing what it is.

If your findings differ or you’ve got first-hand experience that adds to (or challenges) any of this, I’d love to hear it — always open to sharpening the insights.

Had a ’22 Platinum that I sold for a different platform, now coming back to do a full build on a ’25 Platinum (converting it to ST specs like last time). Spent considerable time researching the diff brace landscape and wanted to share my findings — both to help others and get feedback from those further along.

Brace Comparison: Key Options for the Platform

ID Speed ($499)

• Most consistent praise across Explorer builds

• Engineered like a 4-bolt system

• Uses EPDM bushings for superior NVH control vs. poly

• Ideal for daily-driven or mixed-use builds

• No major complaints found during research

AWR Racing ($280)

• Excellent value option with solid design

• However, some concerning red flags:

• Marketing claims about police fleet use unverifiable

• “Lifetime warranty” contradicted by fine print (“racing use only”)

• Works well for many, but integrity concerns may be dealbreakers for premium builds

Steeda ($550)

• Multiple reports of excessive NVH

• Design appears too rigid for daily-driver comfort

• Documented mounting bolt failures under load

Livernois (SEMA 2024 release)

• Similar to Steeda design but not identical

• Uses premium ARP hardware

• Too new for real-world data

• Like Steeda, appears better suited for track use due to stiffer design

Bottom Line

• Go ID Speed if budget allows – best engineering, clean install, solid support, minimal NVH

• AWR works but proceed cautiously – great price, questionable marketing

• Avoid Steeda unless prioritizing track times over comfort

• Livernois is unproven – worth monitoring but not recommended (yet) for daily builds

Troubleshooting NVH or Whine After Brace Install

Something that kept appearing across platforms — Mustang, Camaro, Trackhawk, Explorer:

Braces rarely cause noise. They reveal it.

Installing a brace replaces soft factory bushings with solid mounts, transmitting more vibration and sound into the chassis. Early wear in your pinion bearing, gear mesh, or carrier preload — previously masked — suddenly becomes audible.

If You Hear New Noise After Install

1. Don’t assume the brace is to blame

• Remove the brace temporarily. If noise disappears, the problem was likely already developing inside the diff.

2. Log noise patterns

• Speed (45–50 mph, 58–62 mph are common problem zones)

• Throttle input (accel vs. decel)

• Temperature, road surface, etc.

→ Helps differentiate gear whine from bearing drone or bushing resonance.

3. Send diff fluid for analysis

• Use a lab like Blackstone

• High iron = bearing wear

• Brass/bronze = gear or thrust washer wear

→ Confirms preexisting issues.

4. Check for Ford TSBs

• Some Explorer models have known diff/pinion issues

• The brace might simply be surfacing a documented problem

5. Verify brace torque and alignment

• Over-tightened or misaligned installations can cause vibration

• Confirm clean seating, correct torque spec, and no diff preload

6. Use chassis mic or mechanic’s stethoscope (if available)

• Helps isolate whether sound originates from diff, half shafts, or elsewhere

• This approach saved several users from misdiagnosing axle issues as diff problems

Final Thought

• If a brace makes something louder — it may be doing you a favor.

• Better to hear early-stage wear now than experience a $3000+ failure later.

• Whether you’re building from scratch or doing a conversion like me — understanding what the brace isn’t doing is just as important as knowing what it is.

If your findings differ or you’ve got first-hand experience that adds to (or challenges) any of this, I’d love to hear it — always open to sharpening the insights.

-

4

- Show All

- Messages

- 2,906

- Reactions

- 1,306

- Points

- 252

- Location

- Nevada

- Vehicle

- '20 Raptor, '22 Explorer ST, '14 GT500, '03 F150

Appreciate everyone sharing their experiences here — doing research for my next build and found this thread incredibly helpful.

Had a ’22 Platinum that I sold for a different platform, now coming back to do a full build on a ’25 Platinum (converting it to ST specs like last time). Spent considerable time researching the diff brace landscape and wanted to share my findings — both to help others and get feedback from those further along.

Brace Comparison: Key Options for the Platform

ID Speed ($499)

• Most consistent praise across Explorer builds

• Engineered like a 4-bolt system

• Uses EPDM bushings for superior NVH control vs. poly

• Ideal for daily-driven or mixed-use builds

• No major complaints found during research

AWR Racing ($280)

• Excellent value option with solid design

• However, some concerning red flags:

• Marketing claims about police fleet use unverifiable

• “Lifetime warranty” contradicted by fine print (“racing use only”)

• Works well for many, but integrity concerns may be dealbreakers for premium builds

Steeda ($550)

• Multiple reports of excessive NVH

• Design appears too rigid for daily-driver comfort

• Documented mounting bolt failures under load

Livernois (SEMA 2024 release)

• Similar to Steeda design but not identical

• Uses premium ARP hardware

• Too new for real-world data

• Like Steeda, appears better suited for track use due to stiffer design

Bottom Line

• Go ID Speed if budget allows – best engineering, clean install, solid support, minimal NVH

• AWR works but proceed cautiously – great price, questionable marketing

• Avoid Steeda unless prioritizing track times over comfort

• Livernois is unproven – worth monitoring but not recommended (yet) for daily builds

Troubleshooting NVH or Whine After Brace Install

Something that kept appearing across platforms — Mustang, Camaro, Trackhawk, Explorer:

Braces rarely cause noise. They reveal it.

Installing a brace replaces soft factory bushings with solid mounts, transmitting more vibration and sound into the chassis. Early wear in your pinion bearing, gear mesh, or carrier preload — previously masked — suddenly becomes audible.

If You Hear New Noise After Install

1. Don’t assume the brace is to blame

• Remove the brace temporarily. If noise disappears, the problem was likely already developing inside the diff.

2. Log noise patterns

• Speed (45–50 mph, 58–62 mph are common problem zones)

• Throttle input (accel vs. decel)

• Temperature, road surface, etc.

→ Helps differentiate gear whine from bearing drone or bushing resonance.

3. Send diff fluid for analysis

• Use a lab like Blackstone

• High iron = bearing wear

• Brass/bronze = gear or thrust washer wear

→ Confirms preexisting issues.

4. Check for Ford TSBs

• Some Explorer models have known diff/pinion issues

• The brace might simply be surfacing a documented problem

5. Verify brace torque and alignment

• Over-tightened or misaligned installations can cause vibration

• Confirm clean seating, correct torque spec, and no diff preload

6. Use chassis mic or mechanic’s stethoscope (if available)

• Helps isolate whether sound originates from diff, half shafts, or elsewhere

• This approach saved several users from misdiagnosing axle issues as diff problems

Final Thought

• If a brace makes something louder — it may be doing you a favor.

• Better to hear early-stage wear now than experience a $3000+ failure later.

• Whether you’re building from scratch or doing a conversion like me — understanding what the brace isn’t doing is just as important as knowing what it is.

If your findings differ or you’ve got first-hand experience that adds to (or challenges) any of this, I’d love to hear it — always open to sharpening the insights.

Had a ’22 Platinum that I sold for a different platform, now coming back to do a full build on a ’25 Platinum (converting it to ST specs like last time). Spent considerable time researching the diff brace landscape and wanted to share my findings — both to help others and get feedback from those further along.

Brace Comparison: Key Options for the Platform

ID Speed ($499)

• Most consistent praise across Explorer builds

• Engineered like a 4-bolt system

• Uses EPDM bushings for superior NVH control vs. poly

• Ideal for daily-driven or mixed-use builds

• No major complaints found during research

AWR Racing ($280)

• Excellent value option with solid design

• However, some concerning red flags:

• Marketing claims about police fleet use unverifiable

• “Lifetime warranty” contradicted by fine print (“racing use only”)

• Works well for many, but integrity concerns may be dealbreakers for premium builds

Steeda ($550)

• Multiple reports of excessive NVH

• Design appears too rigid for daily-driver comfort

• Documented mounting bolt failures under load

Livernois (SEMA 2024 release)

• Similar to Steeda design but not identical

• Uses premium ARP hardware

• Too new for real-world data

• Like Steeda, appears better suited for track use due to stiffer design

Bottom Line

• Go ID Speed if budget allows – best engineering, clean install, solid support, minimal NVH

• AWR works but proceed cautiously – great price, questionable marketing

• Avoid Steeda unless prioritizing track times over comfort

• Livernois is unproven – worth monitoring but not recommended (yet) for daily builds

Troubleshooting NVH or Whine After Brace Install

Something that kept appearing across platforms — Mustang, Camaro, Trackhawk, Explorer:

Braces rarely cause noise. They reveal it.

Installing a brace replaces soft factory bushings with solid mounts, transmitting more vibration and sound into the chassis. Early wear in your pinion bearing, gear mesh, or carrier preload — previously masked — suddenly becomes audible.

If You Hear New Noise After Install

1. Don’t assume the brace is to blame

• Remove the brace temporarily. If noise disappears, the problem was likely already developing inside the diff.

2. Log noise patterns

• Speed (45–50 mph, 58–62 mph are common problem zones)

• Throttle input (accel vs. decel)

• Temperature, road surface, etc.

→ Helps differentiate gear whine from bearing drone or bushing resonance.

3. Send diff fluid for analysis

• Use a lab like Blackstone

• High iron = bearing wear

• Brass/bronze = gear or thrust washer wear

→ Confirms preexisting issues.

4. Check for Ford TSBs

• Some Explorer models have known diff/pinion issues

• The brace might simply be surfacing a documented problem

5. Verify brace torque and alignment

• Over-tightened or misaligned installations can cause vibration

• Confirm clean seating, correct torque spec, and no diff preload

6. Use chassis mic or mechanic’s stethoscope (if available)

• Helps isolate whether sound originates from diff, half shafts, or elsewhere

• This approach saved several users from misdiagnosing axle issues as diff problems

Final Thought

• If a brace makes something louder — it may be doing you a favor.

• Better to hear early-stage wear now than experience a $3000+ failure later.

• Whether you’re building from scratch or doing a conversion like me — understanding what the brace isn’t doing is just as important as knowing what it is.

If your findings differ or you’ve got first-hand experience that adds to (or challenges) any of this, I’d love to hear it — always open to sharpening the insights.

-

1

- Show All

AWR is a perfectly good brace for 1-bolt cars, it doesn’t do as good as a job as the ID-Speed for 1-bolt cars. For 2-bolt cars, since the AWR is asymetrical it has a weird torsional effect with the left bushing. I don’t like it for 2-bolt cars but for 1-bolt cars it does the job if you’re on a budget.

https://www.facebook.com/share/v/19gcBMsj9r/?

Last edited:

-

2

-

1

- Show All

- Messages

- 2,906

- Reactions

- 1,306

- Points

- 252

- Location

- Nevada

- Vehicle

- '20 Raptor, '22 Explorer ST, '14 GT500, '03 F150

That weird torsional effect you mention happens even more on the one bolt cars. The first videos showing it were a one bolt car. **** it’s hard for me to type that…they’re 3 and 4 bolt, not 1 and 2. lol

https://www.facebook.com/share/v/19gcBMsj9r/?

https://www.facebook.com/share/v/19gcBMsj9r/?

That weird torsional effect you mention happens even more on the one bolt cars. The first videos showing it were a one bolt car. **** it’s hard for me to type that…they’re 3 and 4 bolt, not 1 and 2. lol

https://www.facebook.com/share/v/19gcBMsj9r/?

https://www.facebook.com/share/v/19gcBMsj9r/?

-

1

- Show All

- Messages

- 2,906

- Reactions

- 1,306

- Points

- 252

- Location

- Nevada

- Vehicle

- '20 Raptor, '22 Explorer ST, '14 GT500, '03 F150

Explorer ST Posts

-

-

-

Welcome to the Explorer ST Forum, please post an introduction

- Latest: Nascarbilly

-

-

-