-

Sign Up! To view all forums and unlock additional cool features

Welcome to the #1 Explorer ST Forum and Explorer ST community dedicated to Explorer ST owners and enthusiasts. Register for an account, it's free and it's easy, so don't hesitate to join the Explorer ST Forum today!

Steeda Subframe bushings

- Thread starter Raym80

- Start date

Easy install, about 45 minutes. Watching the Steeda video is all you need. Car feels more stable, connected. Would definitely recommend after all the usual mods have been done. Not a lifechanging difference but for many, will add to driving enjoyment.

-

1

- Show All

- Messages

- 304

- Reactions

- 185

- Points

- 37

- Location

- Sacramento, CA, USA

- Vehicle

- 2021 Explorer ST Carbonized Gray

I installed these bushings today, it took about an hour and a half wheels up to wheels down. The bushings fit perfectly and the install went smooth since Steeda's instructions were spot on. I did remove the rear wheels for more space which makes the install much easier. I recommend leaving one sub-frame bolt loosened but installed to prevent any alignment issues when re-installing the bolt. I haven't drove it yet since the install was cutting into my drinking time, but I will drive it this week.

I want to thank Steeda and John Marton for great customer service, there was some issues with their new shipping insurance but they made sure I was taken care of. Thank you.

I want to thank Steeda and John Marton for great customer service, there was some issues with their new shipping insurance but they made sure I was taken care of. Thank you.

-

2

- Show All

Another install done, took about 90 minutes including tool gathering and driving up on ramps. Didn’t remove the rear wheels and it was no problem, especially on my 8” lift Race Ramps. It was also necessary to unbolt the rear exhaust hangers and slide the pipes to get at one of the bolts on those rear frame brackets, which isn’t mentioned. I couldn’t care less about drag racing, but any improvements that can be made (i.e., stiffen) an IRS rear is well worth it, so I’m glad to have them in. Didn’t hurt that they were only around $200 when I bought them a month or two back.

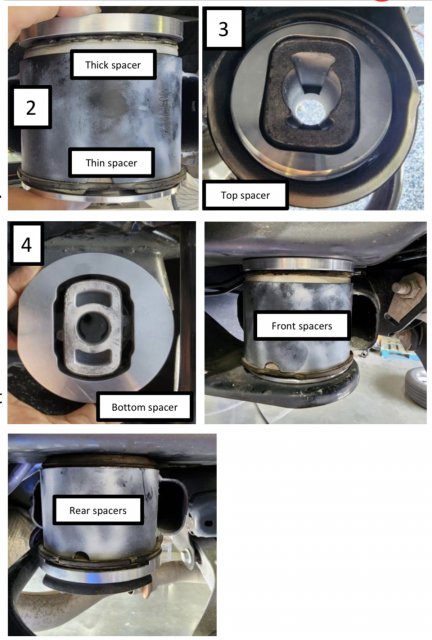

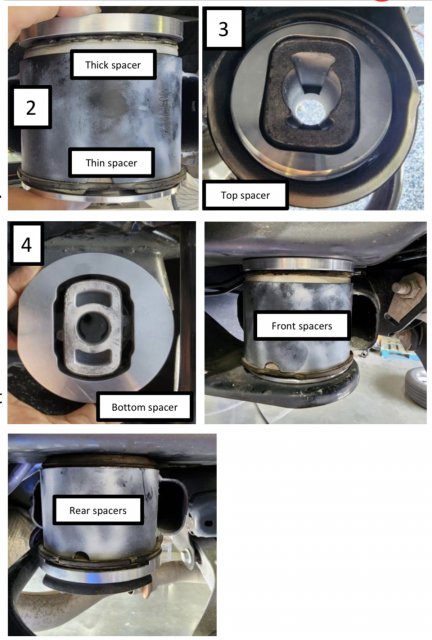

Here’s a screen shot of the Steeda instructions that show the location of each insert as an FYI. Between their instructions and the video, it’s a cinch.

Here’s a screen shot of the Steeda instructions that show the location of each insert as an FYI. Between their instructions and the video, it’s a cinch.

-

2

- Show All

While these are probably much easier to install, wouldn't solid rear subframe bushings result in the best performance?

-

1

- Show All

If you want to drop your entire rear subframe, burn out the OE rubber, clean the mounting shells, and add poly bushings (assuming ANYONE actually makes them), then put everything back together, feel free to report on how it turns out…after a day or two of labor.

NVH would go through the roof with a solid mount or even a poly bushing. Firming things up is fine but not everything needs to be hard mounted.

Many OEMs actually use different (and solid) bushings for performance variants. One that would come to mind is your regular BMW 3 Series vs M3 on the F8X and G8X platforms. Another example would be the rear subframe bushings on the 6th Gen Camaro.

I've actually replaced my factory rubber rear subframe bushings with solid rear subframe bushings and it results in almost no NVH increase. Now if I were to replace the following bushings, you would most definitely feel an increase in NVH:

1. rear differential bushings

2. rear control arm bushings with control arms using uniball bushings

3. solid engine mounts

Suffice to say if people are not experiencing any increase in NVH from these rear subframe bushing inserts, chances are NVH is fairly inelastic to the hardness of rear subframe bushings.

- Messages

- 417

- Reactions

- 400

- Points

- 67

- Location

- Rancho Santa Margarita, CA, USA

- Vehicle

- 2020 Explorer ST

@Polo08816 Regardless of if the NVH would increase or not, full bushing replacement wouldn't be worth the work. These are very cheap and take 60 minutes (if you are slow) to install on jack stands on your garage floor. I've felt a noticeable improvement not only in launching but in just daily driving with these. And there is ZERO change to NVH. I highly doubt the improvement, if any improvement at all, beyond these Steeda inserts in handling or launching with solid Delrin or full poly bushings is worth the increased effort, increased time, and (maybe minor, maybe major) increase in NVH.

-

2

- Show All

@Polo08816 Regardless of if the NVH would increase or not, full bushing replacement wouldn't be worth the work. These are very cheap and take 60 minutes (if you are slow) to install on jack stands on your garage floor. I've felt a noticeable improvement not only in launching but in just daily driving with these. And there is ZERO change to NVH. I highly doubt the improvement, if any improvement at all, beyond these Steeda inserts in handling or launching with solid Delrin or full poly bushings is worth the increased effort, increased time, and (maybe minor, maybe major) increase in NVH.

On a vehicle that I'm going to track, I wouldn't stop at inserts if there is a reputable aftermarket source that has solid Delrin or full aluminum subframe bushings that is being used in a motorsports application. I've run across very few platforms where people have complained about NVH from solid subframe bushings. But chances are that a vehicle that was marketed or designed to be tracked would likely already have a solid mounting of the rear subframe to the chassis.

The labor's intensive, no doubt. A hydraulic press is preferable to burning out the OE rubber just to be able to push it out. I'm not aware of anyone making poly (or solid) bushings.

NVH would go through the roof with a solid mount or even a poly bushing. Firming things up is fine but not everything needs to be hard mounted.

Has anyone with the 1 bolt rear subframe installed these and do they fit? My 21 ST has the 1 bolt and my vin search at the dealership shows part number MB5Z-5035-J and I'm assuming that's the 2 bolt? I want to buy these along with the rear diff brace but want to make sure they fit. Thanks

Explorer ST Posts

-

High pitch humming noise when driving.

- Latest: 2020FordRaptor

-

Welcome to the Explorer ST Forum, please post an introduction

- Latest: Nascarbilly

-

-

-